Billions of years required for natural formation of diamonds You didn’t misread. It takes a ridiculous amount of time and (of course) effort to reach and mine natural diamonds. They form at about 100 miles deep in the Earth’s mantle where the high temperatures and pressures necessary to form diamonds can be reached. Very few places in the world are capable of producing earth-created diamonds. Therefore, the more we learn about natural gems, about the damage done to our planet in order to get them, the more we start looking at man-made ones with special eyes.

What’s a lab-grown diamond?

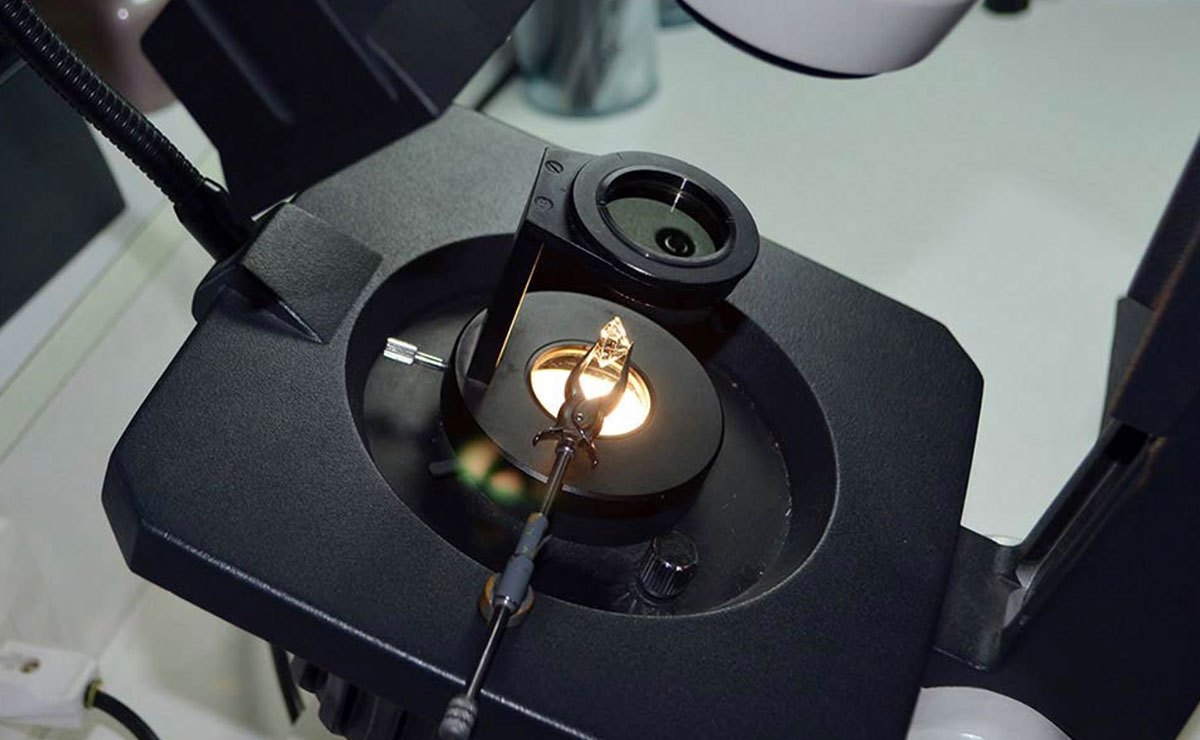

Basically it’s a diamond manufactured in simulated “below-ground” conditions in a lab and it ́s chemical composition is just carbon, exactly the same as natural diamonds. They are grown from tiny carbon “seeds” that develop in these chambers over months, as scorching gasses deposit carbon atom-by-atom onto the original seed. Lab created diamonds even develop their own unique characteristics (inclusions, clarity, etc.) along the way, and once they’re fully grown, they’re cut into the shape that suits their qualities best.

In what way are they different from natural diamonds?

The diamond-growing process is less resource-intensive than the diamond-mining process. It simply costs less to grow a diamond in a lab than it does to mine a diamond from the earth, and those savings are passed along to diamond shoppers. Cheaper my friend. They look the same to the eye, same optical, physical, and chemical properties but are benevolent with the environment and of course, your economy.

Lab-Created Diamonds are Real Diamonds

There are some diamond simulants, like cubic zirconia or moissanite, that are not one thing or the other. Not mined nor lab grown diamonds. These gem materials have different properties to those of diamonds. Though they may resemble or “simulate” the appearance of diamonds, they are not diamonds.

4ct Oval solitaire engagement ring

About lab-grown diamonds’ history

By 1797, diamonds were discovered to be composed from pure carbon, but was only by 1954 that the GE created the first proven man-made diamond. They tried different temperatures and methods, but it wasn’t until the resulting material broke the scientists ́s cutting tools that they thought they had succeded. Because you know, it is said that diamonds can famously scratch and destroy metal tools. However the diamonds were too small for gem use, instead were useful for industrial purposes.

The method initially developed by GE was a high temperature/high pressure process, which mimicked diamond-forming conditions underground but this turned out being expensive and complex.

Today, most lab-grown diamonds are made through a process called chemical vapor deposition, CVD. This can happen at lower pressure and temperature, which makes the process much less costly.

The first patent for CVD was issued in the 1950s but gem-quality diamonds weren’t produced until three decades later. And it took even longer for scientists to make this process commercially viable, since only one seed could undergo CVD at a time and that was quite costly. Now, dozens of seed diamonds can undergo CVD at once.